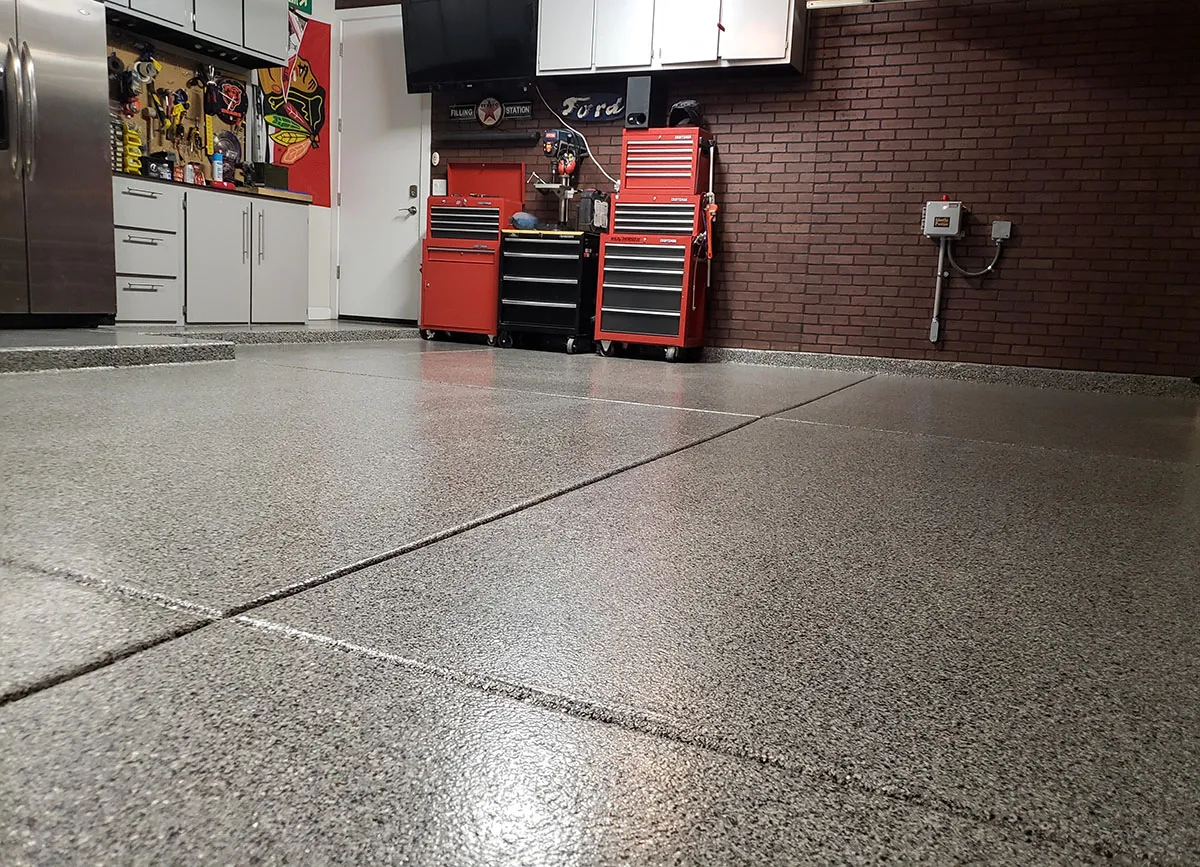

In Houston, your garage is more than a storage space — it’s where projects happen. Whether you’re fixing engines, building furniture, or restoring something old, your workshop demands flooring that can keep up. Unfortunately, most homeowners are working on bare concrete, which brings more hazards than help. That’s where GFC of Houston’s hybrid epoxy and polyaspartic garage flooring makes all the difference.

1. Damage from Dropped Tools and Heavy Equipment

Houston workshops see their fair share of wear and tear. One dropped ratchet or saw can chip concrete and ruin your floor. But GFC of Houston’s garage flooring provides extreme impact resistance, so you can work with confidence knowing your floor won’t suffer from the daily wear and tear.

2. Stubborn Stains from Harsh Chemicals

Whether you’re using degreasers, wood stains, or motor oil, workshop spills are inevitable. On porous concrete, they soak in fast and stay forever. GFC of Houston’s concrete coating system offers extreme chemical resistance, so you can wipe up spills without long-term damage—or lingering eyesores.

3. Slips from Dust, Oil, or Humidity

In Houston’s humid climate, moisture doesn’t just come from above—it comes from below too. Moisture beneath the slab wicks up the porous concrete and creates all sorts of issues, like mold, mildew and radon. On poorly-coated floors (like DIY and 1-day coatings), which can provide inadequate anti-skid properties, sawdust, grease or water are a recipe for slips. GFC of Houston concrete coatings include a built-in anti-skid aggregate, helping prevent accidents when things get slick.

4. Moisture Coming Up Through the Slab

Rainy days and saturated ground are common in Houston. GFC of Houston’s system includes a moisture-mitigating 100%-solids epoxy primer coat…it acts as a moisture vapor barrier (MVB). It protects your workspace from future moisture vapor intrusion and high hydrostatic pressures, mitigating against potential peeling and bubbling.

5. Black Marks from Hot Tires

Working on cars? Then you know the pain of hot-tire pickup—those black marks that never come off. GFC of Houston’s dual, 100%-solids polyaspartic top coats resist hot-tire transfer (aka plasticizer migration), keeping your garage flooring looking clean and professional even after hot summer drives.

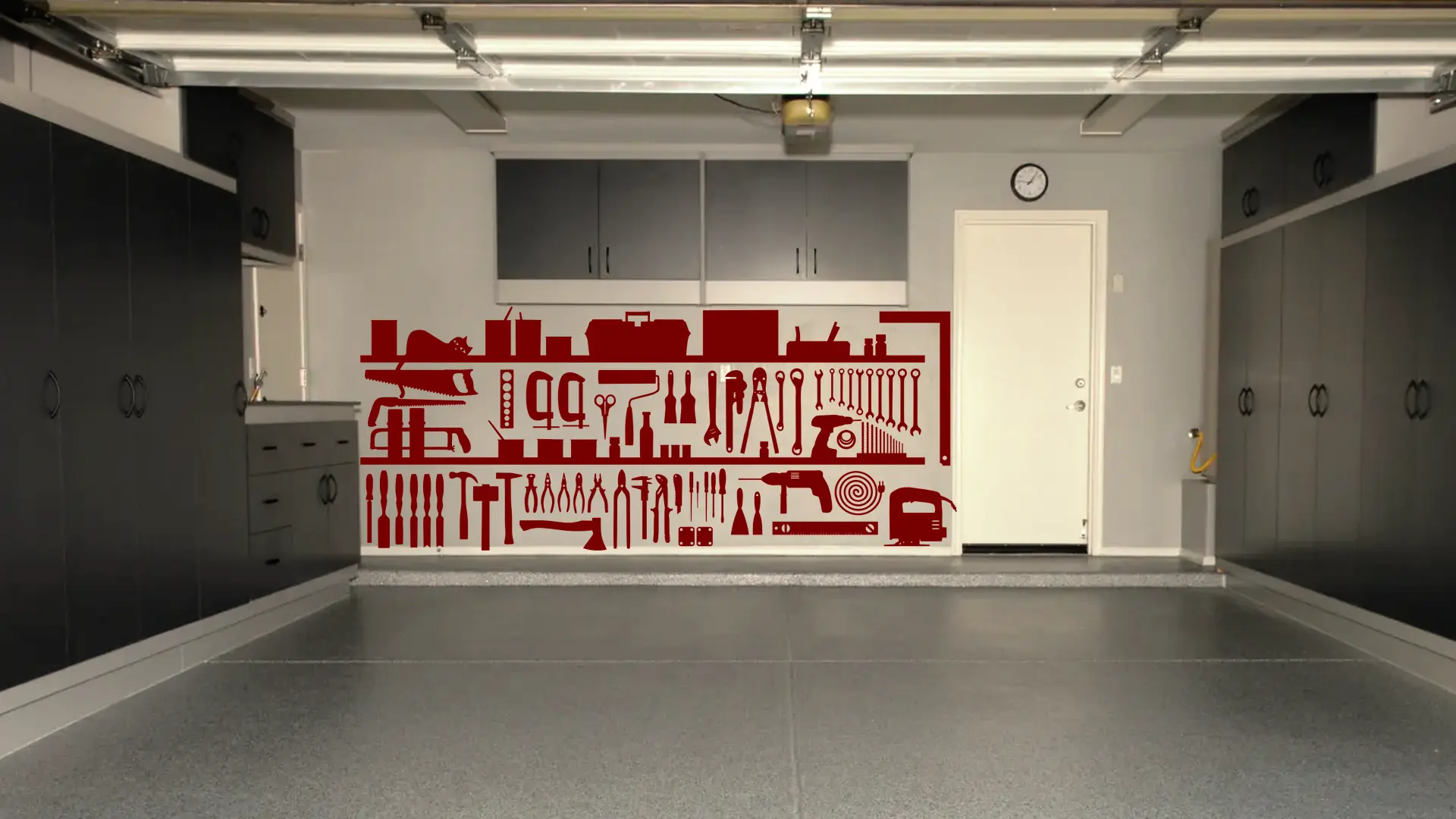

The 2-Day System That Sets GFC Apart

At Garage Floor Coatings of Houston, we install a proven 2-day system. Day 1 includes grinding the surface and applying our slow-curing, thick, moisture-mitigating epoxy base coat. We then broadcast your selected flake blend into the base coat in a full-flake spread. On Day 2, we return to apply two 100%-solids polyaspartic topcoats for long-term durability and chemical resistance. It’s a system designed for hard use—and it shows.

Make your garage workshop safer, cleaner, and stronger. Contact Garage Floor Coatings of Houston today for your custom quote on premium garage flooring.