WE’RE FIGHTING BACK: THE TRUTH ABOUT “1-DAY” COATING SYSTEMS

An article published in August 2020 by GarageFloorCoating.com sheds light on the hazards associated with the utilization of “1-day” coating systems (Polyurea-Polyaspartic One-Day Systems: Do They Work). These widely favored garage floor coating systems have gained significant popularity. Contractors are particularly drawn to them due to their simplicity and efficiency in installation. Similarly, customers value them as the contractor completes the task within a single day. Nevertheless, it is crucial to bear in mind the timeless adage, caveat emptor (“Let the buyer beware”).

It is worth contemplating, particularly within the realm of contractors, how frequently does “fast” translate to “excellent”?

What’s a Polyaspartic?

Polyaspartics are a popular choice for fast-curing coatings in the concrete industry, providing exceptional protection against UV rays, chemicals, and impacts and providing a durable topcoat. They can even prevent tire marks from staining the surface. However, they are not recommended as primer coats directly on concrete in moist conditions due to poor bonding.

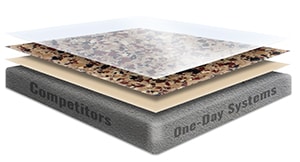

To overcome this, honest contractors use a moisture-mitigating epoxy epoxy as a primer coat before applying the polyaspartic as the clear topcoat. However, because an epoxy takes longer to cure, the installation process can take up to 2 days (not 1). “1-day” contractors try to discredit epoxy products, but it’s important to note that all coating types have their own strengths and limitations. While epoxies are great as primer coats, they’re poor topcoats (due to ambering in the presence of UV light). Conversely, polyureas are excellent topcoats, but a poor choice as primer coat (polyureas can only be put down thinly, so they don’t offer protection against high hydrostatic pressures and thus delaminate).

Contractors who provide a system that claims to be completed within a single day are cognizant of this fact and might attempt to undermine the credibility of epoxy products in order to dissuade potential customers. Additionally, they invariably incorporate a clause in their contract that excludes warranty coverage for any problems related to moisture, thereby safeguarding themselves. It is crucial to acknowledge that all types of coating products, including epoxies, polyurethanes, and polyurea-polyaspartics, possess their own unique strengths and limitations. A reputable contractor should possess a diverse array of products at their disposal to ensure optimal outcomes for each individual project.

Why Don’t “1-Day” Systems Warrant Moisture-Related Issues?

It is not advisable to utilize a thin layer of 70%-80% solids polyaspartic for direct-to-concrete application in “1-day” polyurea-polyaspartic coating systems due to the eventual delamination in environments with medium to high moisture vapor transmission. Contractors opt for this system as it reduces the amount of product and labor required, thereby increasing profitability. Nevertheless, the warranty does not cover “high-moisture conditions” and the potential staining caused by tires, bleach, citrus products, and windshield wiper fluid. Considering these limitations, the investment in a concrete coating may not be deemed worthwhile.

Us Versus Them

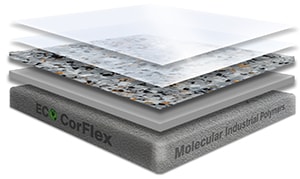

Our thick garage floor coatings are guaranteed against moisture-related conditions and tire staining, as well as most automotive fluids. We take pride in using industrial-grade polyurea-polyaspartic coatings in every garage, applying two clear top coats for maximum protection. It’s important to note that we never use a polyurea as a direct-to-concrete primer…this ensures the longevity of our coatings.

Additionally, our utilization of exclusive mica stone blends in our full-chip, mica stone concrete coatings distinguishes us from the competition. In contrast to others who employ thermoplastic only, our floors possess greater thickness, strength, and visual appeal. The incorporation of an ultra-thick 100%-solids moisture-mitigating primer coat, a full-chip, mica stone broadcast, and two 100%-solids polyurea-polyaspartic top coats with anti-skid in our Bagari SE and Vintage Mica series results in garage floor coatings that are over 35 mils thick. As a testament to our confidence in our product, we offer a warranty against moisture-related issues and “hot tire transfer”…the primary causes of coating system failures.

If you require exceptional, heavy-duty garage floor coatings that are both visually impressive and built to last, please do not hesitate to contact us. Feel free call us or click here for your free estimate. Our primary goal is to offer you the optimal solution for all your garage flooring requirements.